Reorder Point Excel Template

Order too much product and you’re stuck with unsold inventory that’s tying up cash. Order too little and you may lose customers due to being out of stock. How does one solve this common conundrum?

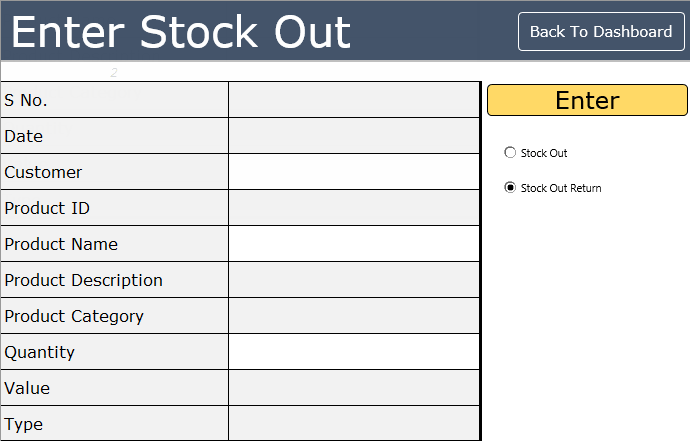

- Reorder Point Excel Template Spreadsheet

- Conditional Formatting For Reorder Points

- Reorder Point Excel Templates

Instead of guessing when it’s the right time to reorder product, try using the reorder point formula to maintain the right level of stock and improve your inventory management controls. While you might think your gut works best as a guide, think again. Lead times are different for many products and this can greatly impact whether you can fulfill every order.

In this post, we’ll explain what a reorder point is and how to calculate it.

What is a Reorder Point?

A reorder point is the threshold, or lowest point, of your safety stock. Your reorder point should also include the lead time you need to bring additional stock into your warehouse. Tamil keyboard windows 7 free download. Essentially, your reorder point indicates when it’s the right time to place an order for new stock.

Reorder points are an extremely important inventory management practice, which helps you to maintain the right levels of stock, thus keeping your buyers happy.

Inventory Reorder Point Excel Template is cost nothing, cross-platform, useful, user-friendly, and flexible. These elements make it an ideal tool to map your plans for all facets of your lifetime and, also, to check out by way of on them. The next sample online Inventory Reorder Point Excel Template will show that. Supply Chain View. The last section of the spreadsheet is the Order Recommendation. Once again, start by entering the labels as shown in the example. In the Order Qty data cell (C26), enter this formula: =IF((C17-C23)0,(C17-C23),0) The formula looks more complicated than it really is. It basically says to subtract the minimum stocking level from the quantity.

We have fed conditions into the inventory Excel template using ‘Conditional Formatting,’ which signifies an alert for you when a stock count reaches or crosses the Reorder point. This helps in alarming you before the stock runs out without the need for you to go through hundreds of cells each time and avoid any mishap. The second is a spreadsheet for calculating reorder points based on risk, seasonal use, and cost-effectiveness: The Top 40 Reorder Tweaker Tool. Top 40 Inventory Tweaker Tool, Part 2 Fearful Hesitant Confident Product Name # of Units Sold Annually Your Normal Reorder Point. The Tweaker Tool Calculates New Reorder Points for You!

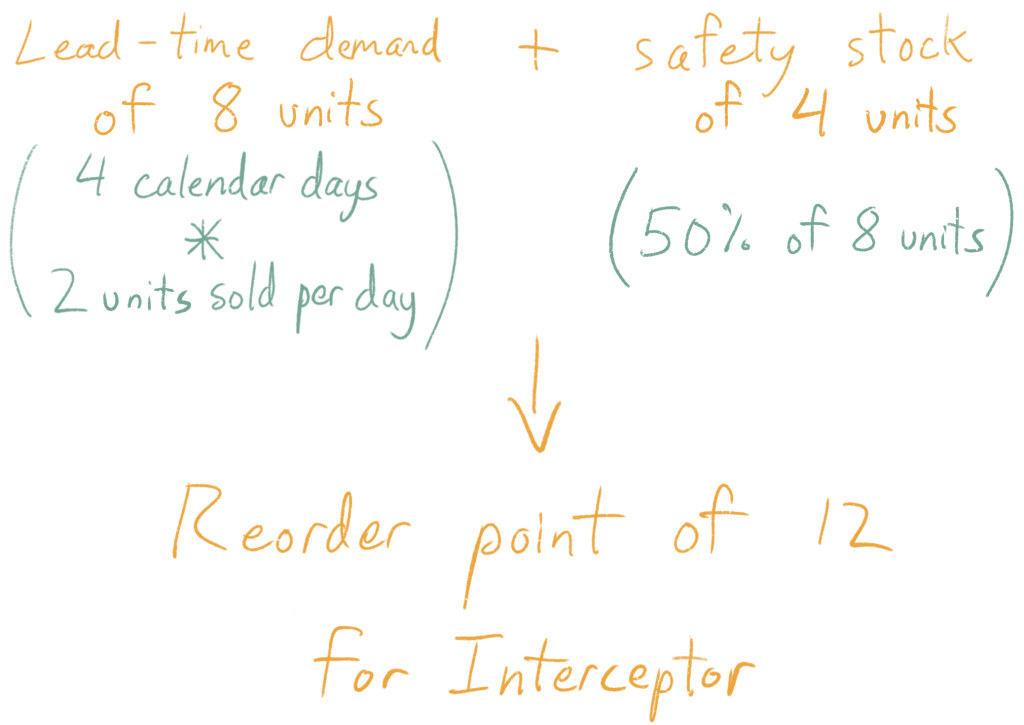

How to Calculate Your Reorder Point

To calculate your reorder point, your formula should be as follows:

Maximum Daily Usage x Maximum Lead Time (in days) + Safety Stock (in days) = Reorder Point

Let’s start with an example and use one of your best sellers, especially since you don’t want to run the risk of losing a sale of a popular item. You just might lose that customer to a competitor and they may never return to do business with you again.

Let’s say that your most popular item is a smart TV. You know that your average daily sales of smart TVs is five per day and the lead time for smart TVs is typically eight days. You have 10 smart TVs reserved within your safety stock. So, your formula would look like this:

Reorder Point Excel Template Spreadsheet

(Maximum Daily Usage) 5 x (Maximum Lead Time) 8 + 10 = (Your Reorder Point) 50

Now, you know that when you reach a minimum of 50 units for this product, it’s time to place an order with your supplier.

Typically, your inventory management software of choice should allow you to set an alert to notify you that you’ve reached your reorder point. When that occurs, your alert reminds you it’s time to send a purchase order to your supplier. This ensures that once you hit the reorder point, your warehouse manager is reminded to place that order.

Conditional Formatting For Reorder Points

If you somehow miss that you’ve gone below your reorder point, your safety stock may be able to save you, but it depends how many orders come in until the new shipment of goods arrives. Keep in mind that your suppliers will likely charge you for a last-minute, rush order, which is one of many reasons why you don’t want to go below the threshold of your reorder point.

Reorder Point Excel Templates

If you’d like to learn how Systum can help you with inventory management and more, fill out the form below.